Vacuum measurement: Modern wide-range gauges

MKS Instruments, Inc.

Contents

Overview

Applications

Modern Sensors

Modern Controllers

A closer look at gauge types

Overview

In the family of thermal conductivity gauges, the Pirani sensor is distinguished by fast response to pressure changes, reasonable cost, compact size, and ease of use. Current solid-state Pirani gauges have an extended pressure range from atmospheric pressure down to as low as 10-5 Torr if the sensor is properly zeroed and the ambient temperature is stable.

Miniaturized direct-reading gauges based on silicon membranes and piezo-electric elements can measure from 0.1 Torr to over 3000 Torr (about 4 atmospheres). Piezo sensors with stainless steel membranes are available that are resistant to corrosive gases.

Thermal conductivity and piezo transducers can be combined in one sensor to provide a wide-range vacuum gauge. Modern controllers add flexibility in terms of integration with the sensor, process automation, calibration to various gases, and the units of pressure readout.

Applications

Many thin film and semiconductor processes such as chemical vapor deposition (CVD), rapid thermal processing (RTP), plasma etch, ion implantation, evaporation and sputter deposition processes take place under reduced pressure ranging from 10-9 Torr to atmospheric pressure. For pressure control of the critical and relatively "dirty" processes such as CVD and etch, capacitance manometers are most appropriate because they are reliable, accurate and less prone to contamination.

Ionization gauges (hot cathode or cold cathode) are often selected for high-vacuum processes such as ion implantation and sputter deposition or ultra-high vacuum processes such as molecular beam epitaxy. Cold cathode gauges are supplanting traditional hot cathode gauges because of several advantages: fast response time, no filament burnout, and less outgassing. However, thermal conductivity gauges such as Pirani and thermocouple gauges (see sidebar) and modern Piezo sensors (to be described later in this article) are extremely useful for higher pressure applications such as foreline/pump, load lock chamber and roughing line pressure monitoring. In addition, thermal conductivity and Piezo gauges are useful for slow-pumpdown control, and vacuum loadlock operation.

In the past, the range between 10-4 Torr and 1 mTorr was difficult to measure accurately with traditional Pirani and ion vacuum gauges. Traditional Pirani sensors rapidly lose sensitivity above about 10 Torr. The convection Pirani gauge has improved high-pressure sensitivity, but suffer from poor accuracy and slow response time and the sensor must be orientated properly. Modern solid-state pressure sensors have changed all that and can now cover this entire range with 1% reproducibility and 0.1% resolution. This article describes some of these advanced pressure sensors that are now available and can be used to monitor medium vacuum and sub-atmospheric semiconductor processes.

Modern sensors

Contemporary microelectronics technology has enabled a significant reduction in size of both thermal conductivity gauges and diaphragm gauges. In addition, microprocessor integrated circuits have greatly expanded the capability of the electronics control unit.

Solid state Pirani gauge

Recently, the Pirani sensor has been miniaturized. For example, the MKS Instruments MicroPirani sensor is fabricated on a one-millimeter square silicon chip. The miniaturization of the traditional Pirani sensor has extended the upper pressure measurement range from 10 Torr to 1000 Torr. This is because the geometry of the sensor (the distance between heat source and heat sink) is less or equivalent to the thickness of the thermal sheath around the filament when the system is near atmospheric pressure. In addition, because the sensor mass and volume are so much smaller, the amount of gas that needs to be heated and the thermal mass of the sensor have been dramatically reduced, which translates into faster sensor response time.

As the MicroPirani sensor is fabricated by using standard semiconductor processes, it is possible to incorporate the bridge circuitry and temperature sensors on the same chip. This improves the consistency of the bridge and also makes temperature compensation easier and repeatable as the sensor is close to the heat sink. With a well-designed temperature compensation circuit and a stable ambient temperature (such as in a clean room) the measurement range can be extended down to 10-5 Torr.

This sensor, as well as most other semiconductor-based sensors, is designed for use in non-corrosive atmospheres, and may not be appropriate for monitoring corrosive atmospheres in processes such as etching and CVD. The material exposed to the process atmosphere include silicon, silicon dioxide, silicon nitride, gold, epoxy resin, aluminum, stainless steel, and Viton fluorocarbon elastomer.

Piezo transducer

A recent innovation in a direct reading manometer is to sense the displacement of a silicon membrane with a piezo transducer. The metal diaphragm is replaced with a thin silicon membrane and a piezoelectric element senses the mechanical strain (displacement) of the membrane. As with other diaphragm-based vacuum sensors, Piezo transducers are direct-reading and gas independent. The silicon membrane is suitable for non-corrosive environments. Corrosion resistance is improved by bonding the piezo sensor to a stainless steel diaphragm in a PiezoSteel transducer.

A Piezo sensor has a pressure measurement range of from 1 to 1000 Torr or 1 to 3000 Torr. Because the sensing diaphragm area is smaller than that of a traditional Baratron capacitance manometer, the sensitivity is less, but it is significantly better than Pirani and convection Pirani sensors. Piezo sensors are quite suitable for less critical applications such as load lock and foreline pressure monitoring. By combining Piezo and MicroPirani elements in the same package, a very small wide-range pressure sensor can be achieved.

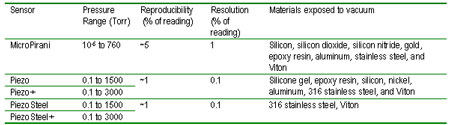

Table I. Pirani and Piezo Pressure Transducers

Pirani, piezo, and wide-range combination sensors are available (See Table). The PiezoSteel sensor has been designed especially for corrosive environments. A stainless steel membrane protects the piezo element and only 316 stainless steel and Viton are exposed to the gas environment being measured. All of these sensors have extended high pressure range up to one atmosphere or higher but since they are direct reading sensors, they can be operated in any position. The sensors have standard ISO-KF NW 16 flanges and an internal volume of only 0.6 cm3. The MicroPirani and piezo sensor are available combined in one transducer (Photo) that covers the pressure range from 10-5 Torr to 1500 Torr (the MKS DualTrans) or from 10-5 Torr to 3000 Torr (DualTrans ).

Modern Controllers

Today's micro circuitry allows several very useful functions to be incorporated in compact, integrated electronic controllers (Photo). For example, you can select the pressure units of the readout to be either Torr, Pascal, or bar. For the Pirani sensor, gas calibrations (as in Figures 1 and 2) for air, nitrogen, argon, helium and hydrogen are built in. Setpoints can be so that high and low pressure signals can activate valves, alarms, process steps, relays, etc.

(Back to Top)

Eric Bopp works in the HPS Products Group of MKS Instruments, Inc.