Basic Lyophilizer Maintenance Helps Assure Good Results

By Matt Dellinger, SP Scientific

As with most scientific equipment, the freeze dryer (aka lyophilizer) is comprised of various components working in harmony to provide the researcher’s desired results. Keeping those subcomponents in good working order helps to assure that the equipment itself does not contribute to process failures or bad results. Routine maintenance and some simple housekeeping rules that can help provide uninterrupted freeze dryer use are reviewed here.

Lyophilizer components typically include:

- Computer System

- Instrumentation System

- Vacuum System

- Mechanical/Refrigeration System

- Product and Condenser Chambers

Computer System:

Often, the most overlooked aspect of dryer maintenance is the computer system on PC-based PLC controllers. It is important to keep the computer system running at peak efficiency and to back-up or archive data files on a periodic basis as per an internally created SOP. It is recommended that data files be backed-up at least once per month, if not more frequently, so that data can always be recovered in case of a computer malfunction.

A hard disk defragment can be run on computer systems that seem to react slowly. However, this should not coincide with an active lyophilization cycle. This check can be performed by the user or by an internal IT department, if available.

When utilizing a stand alone computer on a pivotal piece of research equipment, such as a lyophilizer, it is good practice to minimize the number of other applications on the computer.

Instrumentation System:

The instrumentation system encompasses all of the temperature and pressure sensors on a lyophilizer. In most freeze dryers there is most commonly a minimum of 2 or 3 types of instrumentation systems that require calibration. These usually include various temperature and pressure sensors. Typically “T” type thermocouples are used to measure product temperatures as well as the temperature of the shelf heat transfer fluid and the condenser temperature. Vacuum sensors may be any combination of Pirani and/or Capacitance Manometer type gauges on larger freeze dryers or just a simple thermal conductivity gauge on bench-top units.

Depending on whether the freeze dryer is a GMP production dryer or a non-GMP lab scale dryer, the calibration interval will vary and it should be defined in an internal SOP. The requirement for calibration intervals may be different for different lyophilizers depending on where the lyophilizer is utilized and whether or not it is part of the critical path for the development of a freeze dried product. Good manufacturing processes would suggest that intervals of calibration should ideally start out with a relatively short interval such as calibration every week or every month. If the calibration procedure indicates that the system calibration is relatively stable the interval between calibrations can be increased. In theory there will be an interval at which the system appears to repetitively be out of calibration. At this point the best approach is to back up one calibration interval and utilize that at the time interval for calibration moving going forward. In this way the user has a relatively high degree of assurance that the system is in calibration during each and every run. At a minimum it is recommended that calibration of lyophilizer sensors be carried out at least on an annual basis.

Most calibration routines can be done in-situ by various means. An example would be to utilize a crushed de-ionized ice bath to check product probe thermocouples at zero degrees Celsius. Some temperature sensors can only be calibrated with an electronic temperature simulator. It is recommended that you consult the manufacturer of your system for the best method to use.

In a system with both a Pirani gauge and a Capacitance Manometer, a simple check of the vacuum gauges can be accomplished by running the freeze dryer dry and empty, with a set point of 0mT. Pirani gauges, although they read erroneously high in the presence of water vapor (see Technical Note PRIMARY DRYING END POINT DETERMINATION UTILIZING THE PRESSURE RISE METHOD OR THE CAPACITANCE MANOMETER & PIRANI GAUGE CONVERGENCE METHOD) are typically very stable once calibrated. Once the freeze dryer is allowed to stabilize at a relatively low pressure the Capacitance Manometer and Pirani gauge should be in close agreement. If these gauges are not in agreement and there is a high degree of certainty that the system is completely dry and it has been fully evacuated and pulled down to its maximum low pressure, then it is safe to assume that the system is not in calibration.

When a more thorough check is desired, a vacuum transfer standard should be utilized to verify that the vacuum zero adjustment is within tolerance. Calibration may be provided by an outside service or developed and executed within your own company. Vacuum gauge manufacturers often provide calibration information that may prove to be valuable if developing your own calibration procedures.

Vacuum System:

Every lyophilizer has a vacuum system encompassing a vacuum pump and a product/condensing chamber(s). The vacuum pump can be either a “wet” two stage direct drive pump with oil lubrication or an oil-free “dry” pump.

One method to verify the integrity of the oil is to visually check the color at the end of the cycle. If the color has darkened at a detectible level, it is recommended that the oil be changed at the end of the cycle, while the oil is still warm. Some vacuum pump manufactures isolate the vacuum pump oil level sight glass from the main working oil in the pump itself. If this is the case then the sight glass cannot be utilized to detect vacuum pump oil degradation. Wet pumps also utilize an oil mist eliminator (OME) filter that should be replaced at regular intervals, typically once per year.

Although oil-free vacuum pumps do not require oil changes and do not contribute to vacuum pump oil back-streaming, they do require periodic rebuilding because of the lack of lubrication. Also, they typically are not able to achieve as low of a vacuum level as a wet pump. You will need to consult the pump manufacturer for the recommended interval for maintenance of this type of pump.

Chamber door and/or manifold gaskets are another key part of the overall vacuum system on a lyophilizer and they should be visually inspected before each cycle. The freeze dryer could have one gasket or several, based upon the design of the system. Most rubber or silicon door gaskets require no lubrication unless they have become dry - new gaskets are typically impregnated with oils from their manufacturing process. A common mistake often made is the application of a heavy coat of vacuum grease to the gasket. This will typically attract dirt and contaminates to the grease, thereby defeating any benefit of the vacuum grease. High vacuum type grease should only be used in very small amounts to lubricate the gasket. Never should it be used to fill cracks or splits on a worn gasket. Once a gasket has become cracked, split or damaged it should be replaced. The time interval will vary based upon system usage. Gaskets are typically replaced between one and three years.

Bench-top freeze dryers will typically contain a manifold, adaptor plate and quick-seal valves for attaching flasks. All of these components must be leak-free for the system to reach an acceptable vacuum level. Acrylic manifolds & adaptors plates should be inspected regularly for cracks & etching, especially if organic solvents have been used (many organic solvents require the use of stainless manifolds). The valves should be inspected and cleaned on a periodic basis. All glassware should be inspected for scratches and cracks – even a small scratch can cause a flask to implode when exposed to the pressure differential of a vacuum.

A simple check of the entire vacuum system is to verify the ultimate low pressure (0 mTorr set point) in a clean dry system with the condenser turned on. If the vacuum level will not reach factory specifications, there is either a leak somewhere in the system, or, the vacuum pump needs servicing. (Note: This assumes the pressure gauge has been calibrated and is reading accurately. Also, any filter trap cartridges should be removed before testing as out-gassing may affect the ability of the pump to fully evacuate this system).

A leak rate test can be run on the system to verify the integrity of the chamber(s) and all of the seals. This can be as simple as manually running the system down to a low vacuum set point and then turning off the vacuum pump for a specified time, such as one hour. A leak rate, typically expressed in mTorr/hr, can then be calculated based on the change in vacuum level. Acceptable leak rates are based on the volume of the vacuum chamber. Typical leak rate specifications are less than 60 mTorr/hr for bench-top units, 30 mTorr/hr for pilot-sized freeze-dryers and 15 mTorr/hr for larger production units. Leak rates can also be specified in units of mTorr*L/sec, if the total volume of the system is known. PC-based control systems will often include an automated leak rate test cycle. Leak rate tests should be run periodically, as established in an internal SOP.

Because a leak-rate test can be performed fairly quickly, it is often done on a regular basis, especially in a production environment.

Note: caution should be taken when running a leak test on older systems, especially those that do not have a separate vacuum brake solenoid (VBS) anti-suck back valve built into the vacuum system. Although most vacuum pumps do contain a simple built-in anti-suck back check valve, this valve may often not be fully functioning. If this is the case and the lyphilizer is left in a deep vacuum while the pump is turned off, you run the risk of sucking vacuum pump oil back into the freeze dryer.

Mechanical/Refrigeration System:

Periodic checks of the overall operation of the freeze dryer should be run at regular intervals. This may consist of running a built-in automatic system test cycle, also known as a function test. The function test should be performed at least annually, although quarterly or semi-annual checks are recommended for production systems to uncover system deficiencies that may be developing slowly and not detected during a normal process run. These deficiencies could prove detrimental to the processing of product during future cycles. The function test will check that all of the refrigeration and mechanical components, including compressors, refrigerant charge, valves, heat transfer systems, etc., are working properly.

If an automated function test option is not available, a standard recipe (dry run) could be repeated at regular intervals and the measured temperatures & pressures recorded, checked against the set points and compared to the previous data from running the same cycle. For simple bench-top lyophilizers, the lowest condenser temperature can serve as a check of the entire refrigeration system.

Common equipment issues that may show up are refrigerant leaks, electrical relay failures and valve failures. Running periodic checks on these components can uncover potential problems. It is recommended that someone who is familiar with the mechanical and refrigeration systems on the lyophilizer check these areas if the results of the function test are out of factory specifications. Having preventative maintenance performed on the lyophilizer at regular intervals can reduce issues with product runs by uncovering potential problems. Major freeze dryer manufactures have service staff qualified to perform this type of maintenance.

Refrigeration systems with air-cooled condensers require periodic cleaning of the fins to remove dust & dirt. A vacuum with a nozzle brush can be used, taking care not to bend or damage the fins.

Product/Condenser Chambers:

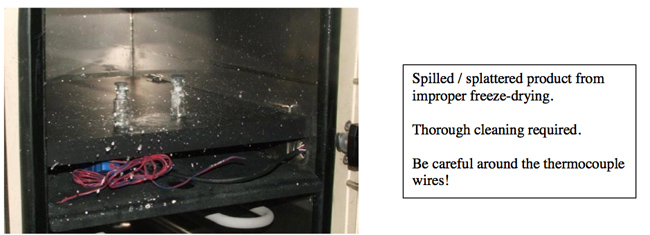

All internal chambers and shelf surfaces should be kept clean. They should be cleaned after each run, making sure to remove any spilled product, broken glass and vial stoppers. Great care should be used around thermocouple wires and jacks. It is good practice to verify that the unit is clean prior to the start of every cycle, especially when there are multiple users in a laboratory environment.

Stainless steel surfaces can be safely cleaned with most alcohols, but care should be used around clear acrylic doors, as some cleaning solvents can etch and craze this type of door. If organic solvents are being used in the product, extra care should be taken to prevent the melted condensate from resting against the condenser door after a cycle. It should be drained immediately and proper steps taken to dispose of the condensate. If acids have been lyophilized during the process, steps should be taken to neutralize this by spraying a PH buffer into the chambers.

Other Maintenance Items:

Following the recommendations in the operations manual is the best method to determine the correct interval for system maintenance. General housekeeping should be used to keep both the inside and outside of the lyophilizer clean. General housekeeping procedures and a calibration schedule should be incorporated into your SOP.

Certain maintenance items not discussed in this document should only be performed by qualified service personnel. Some of these items include:

- Check static pressure in refrigeration system.

- Check refrigeration system for leaks.

- Vacuum pump repair/rebuild.

- Check for heat transfer fluid leaks.

- Solid State Relay Test on microprocessor type controllers