A GC-Based Electronic Nose Simulates Response of Sensor Arrays

Overview

How It Works

High Accuracy and Precision Claimed

Food and Beverage Applications

Overview (Back to Top)

At last month's Sensors Expo conference in Anaheim, CA, Edward Staples, managing director of EST, gave a paper in which he described details of his firm's new odor detection instrument, tradenamed zNose. The unit, he said, is intended as an investigative tool for food and beverage manufacturers, quality control specialists, and olfaction experts.

The instrument can give a recognizable visual image of vapor mixtures (such as fragrances) containing hundreds of different chemical species, the EST official noted. He added that the unit is capable of parts per billion (ppb) sensitivity with volatile compounds and parts per trillion (ppt) sensitivity with semi-volatiles. Direct heating of the GC column of the zNose instrument, Staples said, enables it to separate complex vapor mixtures in "seconds rather than minutes."

How It Works (Back to Top)

As described in the EST paper, input vapors, odors, or fragrances enter the instrument through a temperature-controlled inlet and are preconcentrated in a trap. During sample collection, pure helium carrier gas flows through the GC capillary to a very sensitive surface acoustic wave (SAW) detector. In the analysis phase, the helium stream is diverted to flow through the trap before it flows to the detector. The trap itself is heated with an electrical current to release the vapors inside; the vapors are swept up by the helium carrier gas and delivered to the GC capillary column where they are trapped and focused by the relatively low initial temperature (40°C) of the column. At this point, the temperature of the column is programmed to rise linearly, up to its maximum temperature of 200°C. This causes different chemical constituents of the mixture to be released and travel through the column to the detector.

The SAW detector itself is a piezoelectric device with an uncoated quartz substrate that vibrates at acoustic frequencies. When vapors arrive at the substrate, they get absorbed on its surface and then evaporated. While on the surface, the vapors lower its vibrational frequency; the lowering of the frequency (converted back to an electronic signal) is proportional to the amount of each chemical present in the sample. Identities of each constituent are determined by the time they take to pass through the column and arrive at the detector.

High Accuracy and Precision Claimed (Back to Top)

When calibrated with constant vapor standards, the GC/SAW electronic nose typically achieves 1 to 2% variation (RSD) in readings, EST reports. (Calibration is done with a simple mixture of standard analyte concentrations.) While many SAW detectors are coated with an absorbent layer, the detectors used in the zNose unit are uncoated. One advantage of this, noted Staples in his paper, is that it enhances the stability and sensitivity of the sensor.

According to the EST report, the minimum detection level of chloroform in water with the new unit is 0.65 ppm. Benzene in water can be detected down to 0.96 ppm, and toluene down to 0.15 ppm. The minimum detection level for chloroform in air is 45 ppm; for benzene in air it is 42 ppm, and for toluene it is 11 ppm. The GC/SAW unit is sensitive enough to detect volatiles in drinking water by simply smelling the headspace above a water sample.

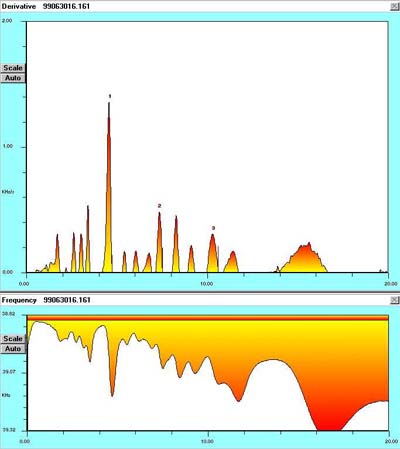

Information from each analysis is presented in the form of frequencies of the SAW detector vs. time, which correlates with the concentrations of the chemicals present and their identities. The peaks can also be viewed as the derivative of SAW frequencies vs. time.

Plots of frequency vs. time (below) and derivatives of frequency vs. time (above) identify constituents of tomato sauce aroma analyzed by the zNose instrument. (Source: Electronic Sensor Technology)

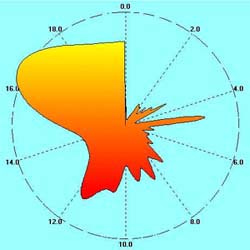

EST has also developed an imaging system that gives a distinct visual pattern for each group of chemicals analyzed. Tradenamed VaporPrint imaging, the system consists of a closed polar plot of the odor amplitude (SAW detector frequency), with radial angles representing sensor time. (Zero and the maximum time are vertical.) With many complex food odors and fragrances, EST notes, it isn't necessary to identify each and every constituent to be able to identify the overall mixture. The visual pattern, which is highly characteristic for many odors and fragrances, is sufficient for identification, just as fingerprints can identify unique individuals.

Food and Beverage Applications (Back to Top)

In his paper, Staples described five areas in which the zNose instrument has been tested. These included analyses of beer, bottled water, sesame oil, whiskey, and wine. Ten-second chromatograms of four common U.S. beers showed little differences in their patterns, so it is not surprising that human taste testers found it hard to distinguish among the four brands. With the bottled water, peak patterns associated with bad taste stood out starkly in the resulting chromatograms.

For the sesame oil, on the other hand, the VaporPrint imaging did not distinguish between seven different grades. So the EST investigators used their instrument to quantify concentrations of the eleven most common compound present in the oil, which enabled them to distinguish different grades of the vegetable oil.

A quick visual image of the tomato sauce aroma pattern is supplied by plotting frequency vs. time on a polar scale. EST calls this approach VaporPrint imaging. (Source: Electronic Sensor Technology)

As for the whiskey, the EST researchers were able to use their instrument to distinguish the aromas of three different types: American Bourbon, French Cognac, and Nikka whiskey from Japan. In wine analysis, the EST team took chromatograms of three different wines: Shiraz, Gewurtztraminer, and Cabernet Sauvignon. The results showed that many of the volatile constituents were the same. But the chromatograms also showed subtle differences that indicated contamination, for example from trichloroanisole, which is formed when bacteria in the corks come into contact with a cork bleaching agent.

In quality control applications, the EST instrument is designed for operation in a fixed location. In that respect, it is not as versatile as the recently introduced handheld Cyrano Sciences "Cyranose 320" unit (see Cyrano Debuts Electronic Nose at Pittcon). On the other hand, EST stresses the reliability of its unit, pointing out that it is the first electronic nose that has been validated by the U.S. Environmental Protection Agency.

For more information: Edward J. Staples, Electronic Sensor Technology, 1077 Business Center Circle, Newbury Park, CA . Tel: 805-480-1994. Fax: 805-480-1984. Email: est@estcal.com.

By Gordon Graff